Under Cabinet Lighting Not Working

Multiple factors are at play when under cabinet lightings stop working. It can be the light’s powering method or the types of bulbs used for the lighting. Under cabinet lighting is often overlooked which is often an inseparable component of a kitchen. As an important kitchen component under cabinet lighting ceasing to work is quite the problem.

Plug-in, Hardwired, and Battery Operated Lights

Plug-in lights are really good for someone to install on their own without any expert help. Plug-ins are quick to install and provide the tasked lighting needed. For a plug-in light to stop working, it has to do with either the plug point or the cord used is faulty. But thanks to how they are built, they are easy to replace.

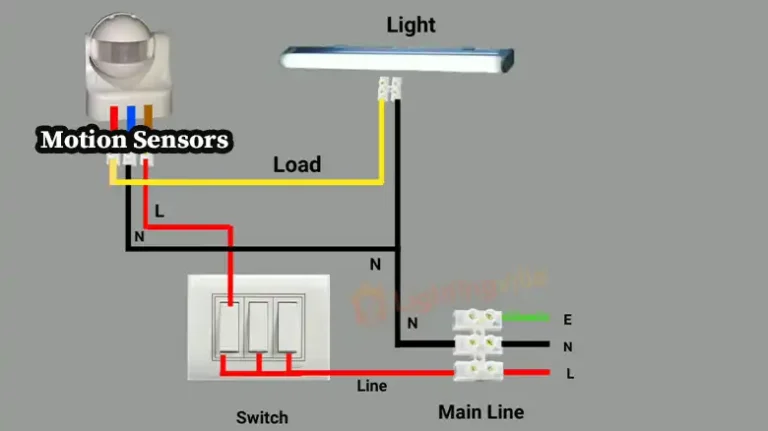

Hardwired lights are operated by a switch. This is quite handy as it lights up the whole cabinet with one single switch instead of plugging in each light. In most cases hardwired lighting not working has to do with connecting the light bulbs with the right sized wire and connectors. A loose connection can also become a fire hazard.

Battery-operated under cabinet light best operates in a small kitchen o. They are operated with a small switch and usually mounted with command tape. The only reason a battery-operated light would stop working is due to the battery being out of charge. This can be easily solved by either changing the battery or recharging them.

Light Bulbs Used Under Cabinets and Their Malfunctions

LED Bulbs

LED lighting is the newest light bulb technology and is rapidly overtaking other light bulb forms due to its energy-saving nature, low heat output, and longevity. Most under-cabinet lighting has a controller with remote control with a plug-in power supply.

If a LED light does not work anymore it’s hardly ever the bulb itself. The most common cause is the remote control. But one of the rare causes is an error in the wiring. The connection between the controller and bulb or stripe should be checked as the connector is very sensitive. The connections should be solid.

If the connection isn’t faulty then the most likely defect is the LED Bulb Controller. Controllers are supplied through a plug-in power supply. To avoid a defect another power supply with the same voltage (usually 12V) should be used for testing. The controller is probably broken if the LED bulb is still dark.

Fluorescent Under Cabinet Lighting

Though LED lights are more energy efficient, fluorescent lights are more efficient than incandescent lights. Fluorescent bulbs produce light by heating the tungsten coils at both ends of the narrow tube. Electrons are passed back and forth which emits UV after colliding with mercury atoms and produces light passing through phosphor coating.

There are plenty of reasons for a Fluorescent Bulb not to work. One of the most common malfunctions is a loose light socket. After necessary precautions, the tube should be removed from the socket. Now wiggling the socket will reveal whether they are loose or not. If it is, it can be easily fixed by screwing the socket tight.

If there is no problem with the socket, the pongs in the socket should be examined. Often times after a period of time the pongs get damaged or oxidized. Before replacing the old pongs their models should be noted to buy the new ones. Any green or white oxidized material is to be removed before placing the new pongs.

Old fluorescent light fixtures use starters also known as ballasts for lighting the tube. Cylindrical shape and silver in color, these are screwed onto the fixture. Old starters lose efficiency which results in no production of light. Pressing and turning the starters anti-clockwise should loosen the starter from the socket.

The fluorescent size is not universal. Different manufacturers have their own dedicated starter sizes and voltages. So when replacing, the old starter should be matched with the new one. Pressing the new starter in and turning it clockwise until tight will set it up. Over-tightening the starter is not recommended.

Xenon Under Cabinet Lighting

Xenon lights are a type of incandescent bulb, which means its light is produced by heating wire filaments. These also contain Xenon gas in the bulb. Xenon is colorless, odorless, tasteless, and chemically very inactive gas. Due to its inactive and cool nature, xenon bulbs are filled with gas. It slows down the decomposition of the wire filament which makes the bulbs last longer.

So if a xenon bulb stops working it’s mostly due to the gas being all used up or the wire filament being burnt off to its last bits. Rather than fixing a xenon bulb, it’s easier to replace it with a new one.

Halogen/ Incandescent Under Cabinet Lighting

Much like xenon, these light bulbs also produce light by heating a wire filament. Halogen bulbs are usually operated through a standard “ON/OFF” switch. However other types of switches tend to be problematic for halogen bulbs. An undersized dimmer switch can easily overheat burn out the bulb and fail the light.

So when a halogen bulb stops working if it’s not the problem with switches then it is most likely the wiring that has a problem. A standard 120v halogen light fixture does not require other than matching black, white, and ground wires together. Most problems occur when a low-voltage halogen light has been installed.

To reduce the amount of voltage coming in a step-down transformer is needed. Failing to use the transformer or bypassing the transformer supplied with some halogen light results in failing the lights. Touching the bulb with bare fingers when installing weakens the glass which then leads to broken filaments rendering it useless.

Conclusion

Under cabinet lighting in a kitchen nowadays is very essential. But this constant problem can be quite an annoyance in daily life. So when installing under-cabinet lighting in the kitchen or open shelves though quite cumbersome much thought and planning should be put into work for a smoother under-cabinet lighting experience.